Double Seal Diagram

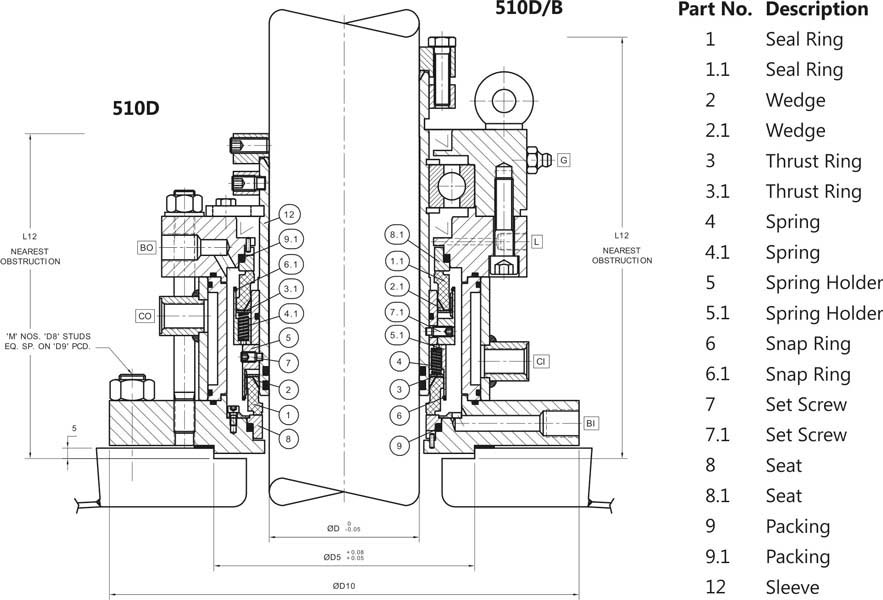

Evolution of double block and bleed valves an alternative to the original two valve system the general valve twin seal plug valve has just one double seated bubble tight valve the upstream and downstream seals provide the same function.

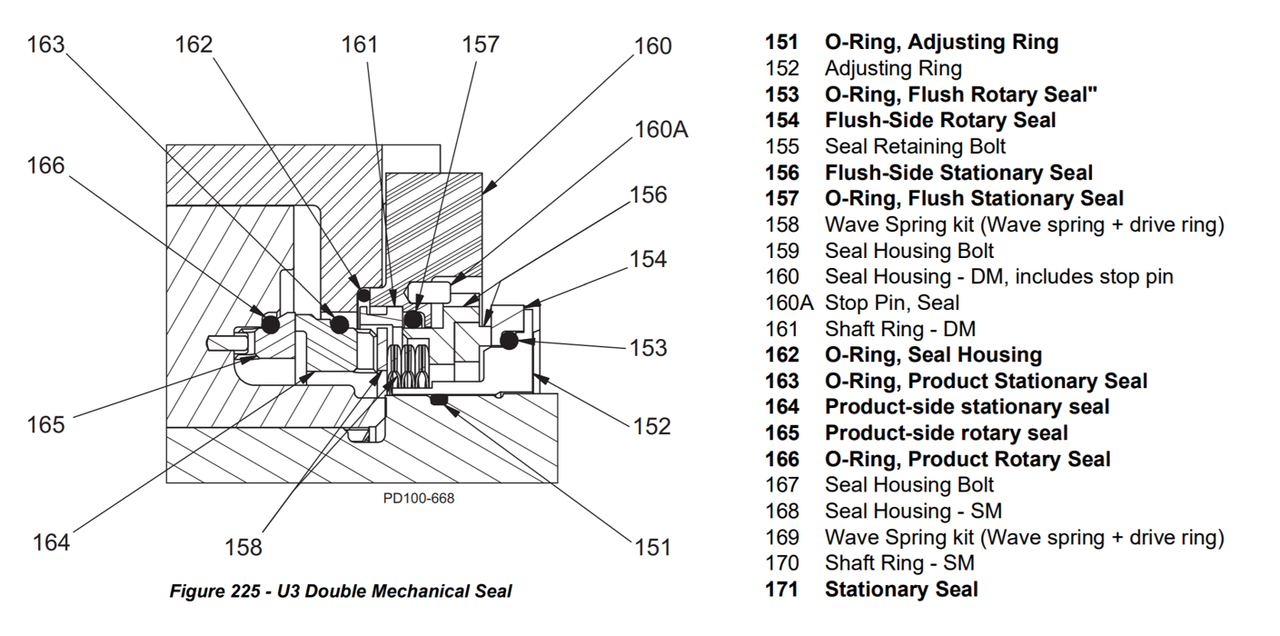

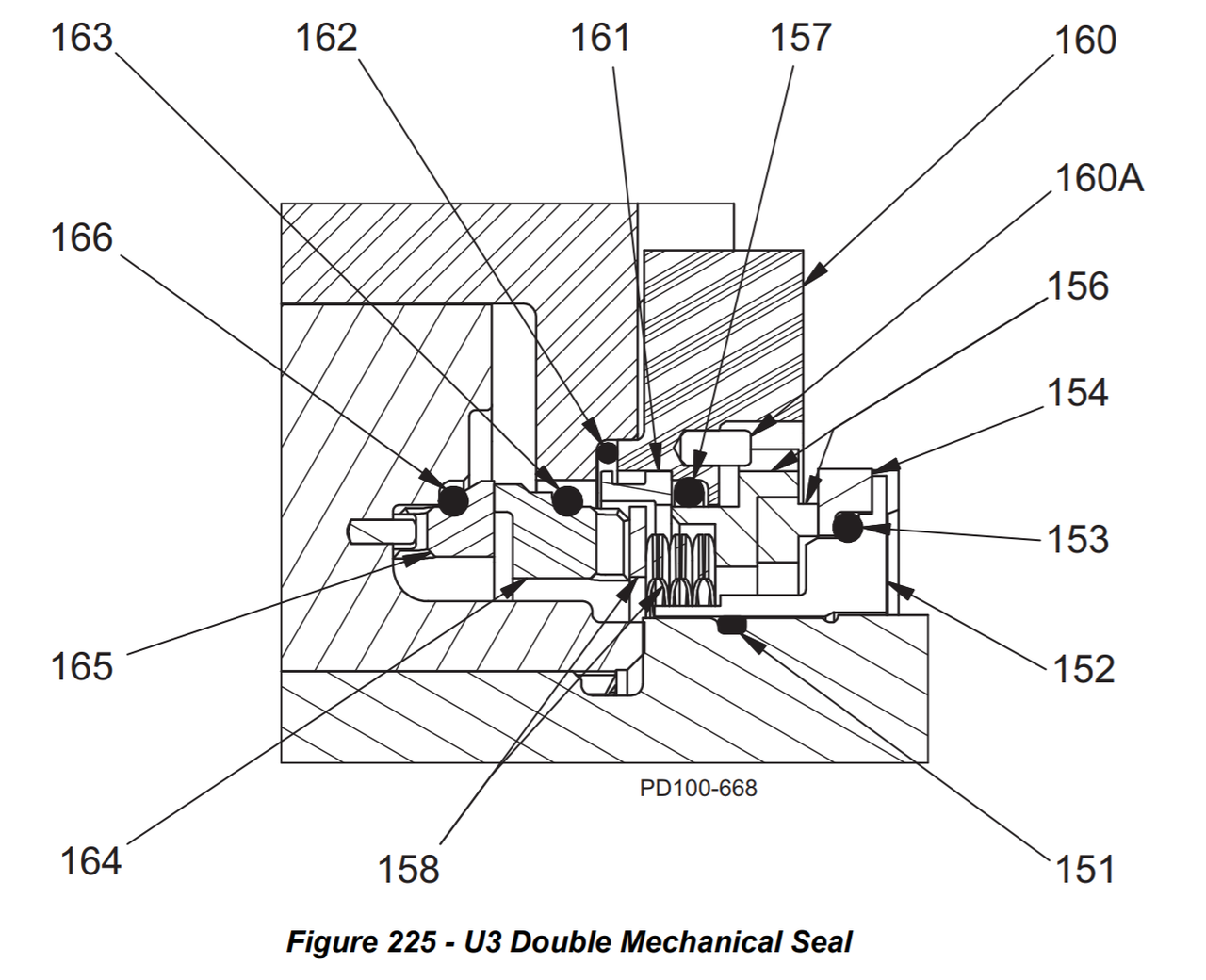

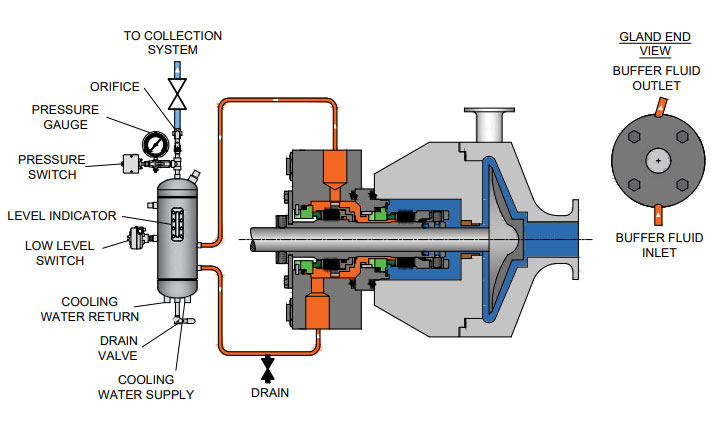

Double seal diagram. Why seal chamber heat removal. The outboard or secondary seal prevents the flush liquid from leaking into the atmosphere. Learn more about garlocks klozure mechanical seals here. The double lip grease seals are usually used in marine applications to give a better seal and protect the bearings from the water which can cause damage to them.

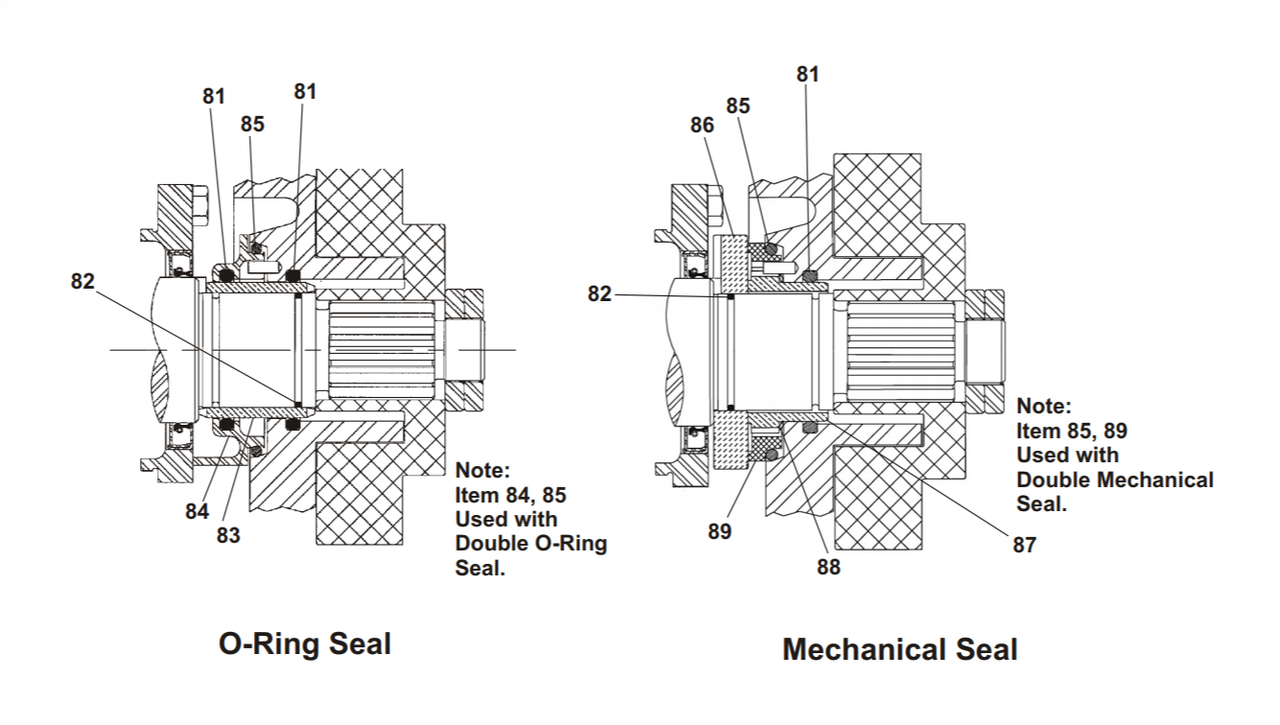

Double seals can help simplify the seal gas control system minimize the quality of seal gas and optimize system reliability. The inboard or primary seal keeps the product contained within the pump housing. Finally it should be noted that there are special single seal housing designs that greatly minimize the abrasives reaching the seal faces even without an external water flush but this is a subject for another column. Where general applications with clean fluids.

The trap seal would remain compromised if the trap seal wasnt restored by the refill tube on a tank type toilet. The difference between the single lip and double lip seals is that the double lip grease seal will have two rubber lips that are in contact with the spindle. Mechanical seals according to en 12756 code system for single mechanical seals there is a distinction drawn between standard n and short k types. Check out the diagram in figure 6 to observe the v parts of a p trap.

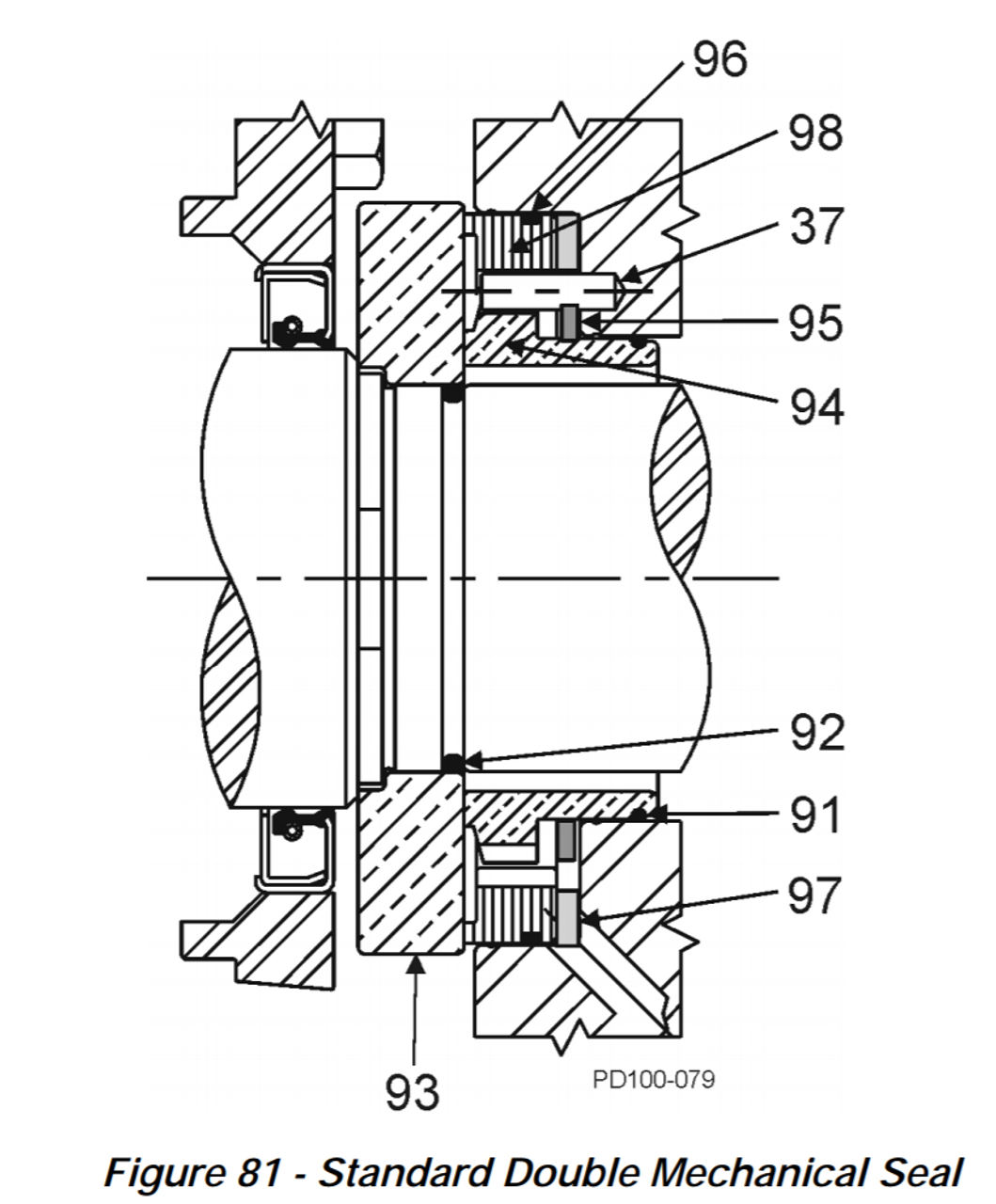

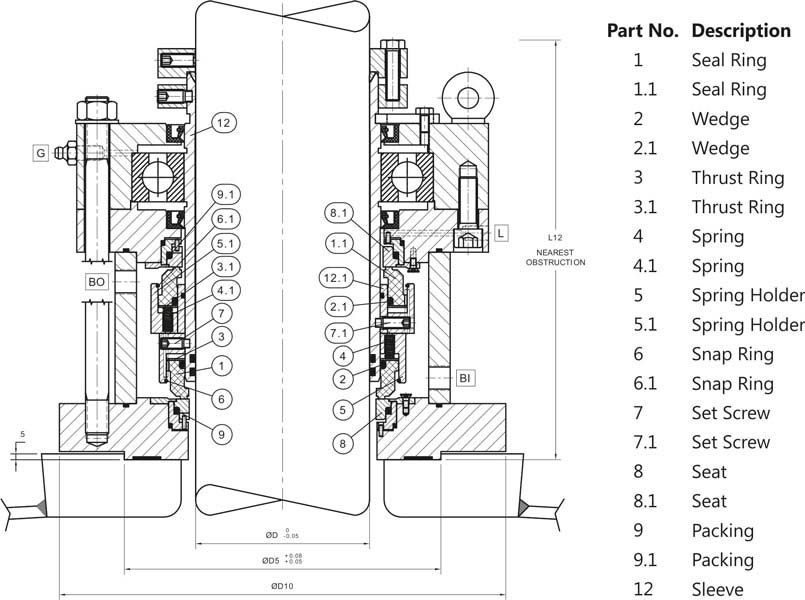

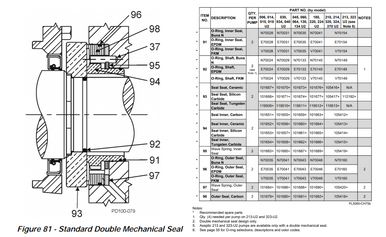

Increase seal chamber pressure and fluid vapor margin. Default single seal flush plan. A double mechanical seal consists of two seals arranged in a series. For double mechanical seals back to back en specifies the short type only.

In part 2 were taking a closer look at the various rotary and stationary double seal arrangement options configurations and how to maximize their success. Double mechanical seals are offered in two arrangements. Double seals are normally applied where an inert seal gas usually n2 which is compatible with the process is available at a pressure exceeding the maximum process pressure at the seal interface to prevent a seal pressure reversal. What is a double mechanical seal.

A video about mechanical seals from the garlock family of companies. Cannot have integral cleanouts. These seals often use two rotating seal faces and two stationary seal. In part 1 of our series on double dual seals we discussed the benefits of dual seal design and when to use it.

Symbols a area of sliding face a h area hydraulically loaded by medium pressure b width of sliding face. Seal chamber venting on horizontal pumps.