6g Welding Certification

A guide to 6g welding and overview of the 6g certification test.

6g welding certification. You can train in various different pipe welding techniques and earn certifications for each of the different pipe welding positions. Covering bevel set up tack welding e6010 open root e7018 hot pass and cap. Basic welding certification cost and where to get certified under any code. So youve decided what qualification you want and youve chosen your welding school.

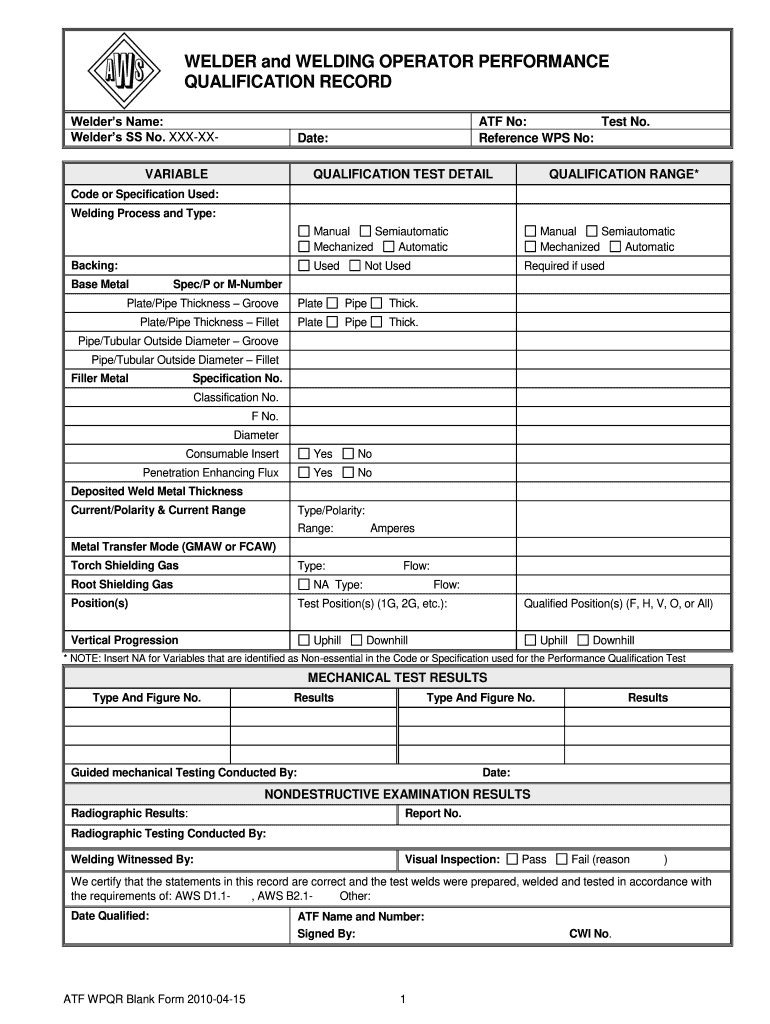

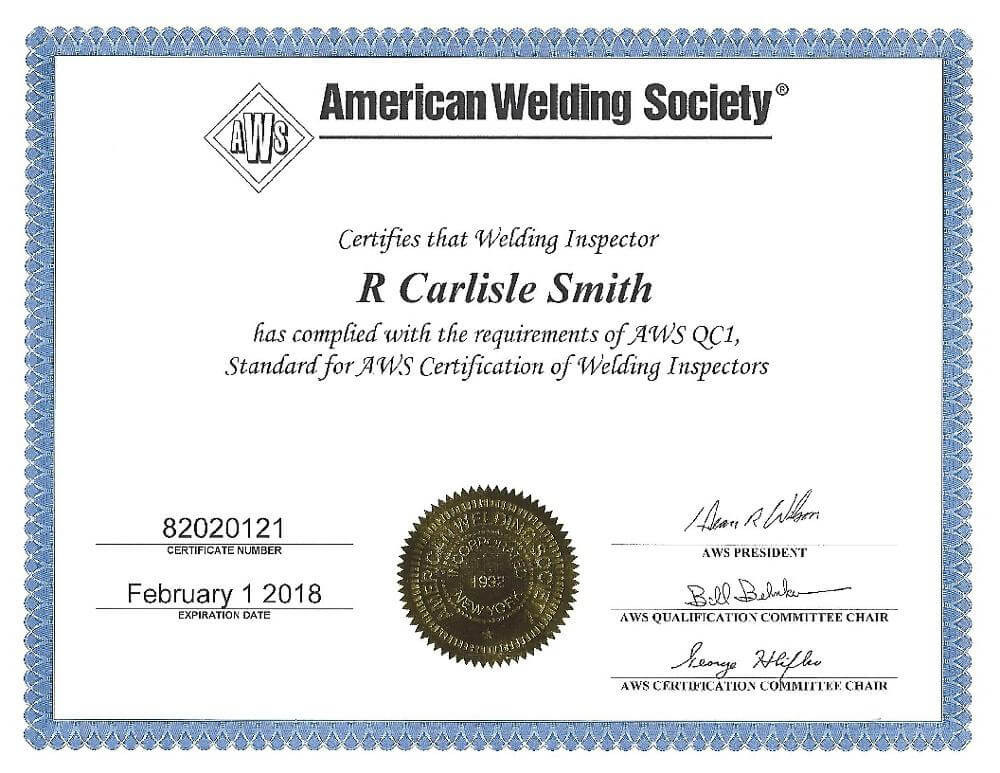

6g welding certification is technically a welder qualification test which is more often than not arranged in pre employment screening to make sure that the welder can perform up to the standards of the employing company. It is kind of like a passage into manhood. Nevertheless a 6g certification is considered the gold standard of the welding profession. This opens up opportunities for more money leadership roles and higher level career challenges.

However as mentioned previously a 6g welding certification is really appealing to many welders and employers because of the high skill level which the technique requires. One of the best ways to advance your welding career is by earning a specialized certification. Plus common welding job qualification tests using dt and ndt inspection. Basic guidelines to becoming a certified welder.

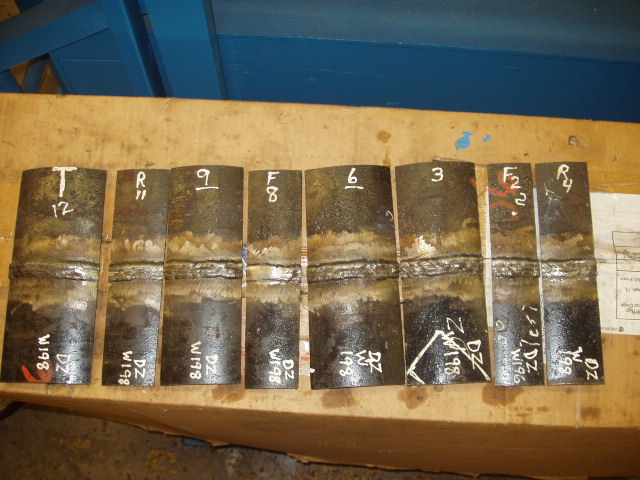

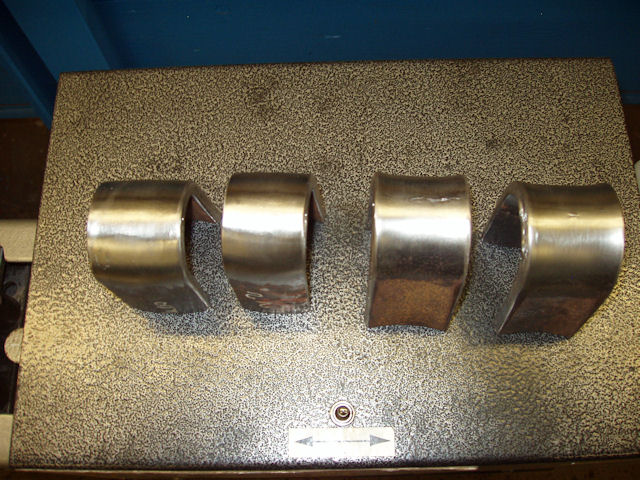

Learn to identify 6g welding the most commonly used kind of weld to test a welder for certification. With detailed accurate information and pictures of the electrode angles machine set up pipe welding techniques and the entire welding certification from start to finish. I remember welding school and passing my first pipe welding test. A grooveweld is a joint in two metal pipes where the space in between them is filled up with the welding material.

Aws offers nine different certification categories from inspectors supervisors and educators to radiographic interpreters welding engineers and fabricators. Pipe welding and everything you need to know how to stick weld pipe to pass a 6g open root pipe welding certification. That would be great. Covering the 1g 2g 3g and 4g positions for plate and 1g 2g 5g and 6g positions for pipe including the restricted tests 6gr.

Just below that is a 5g cert which involves pipe welding in the vertical position. Once you have all the relevant skills the final step in your journey to getting your certification is passing a welding certification test. The letter g stands for the type of weld which is a grooveweld and the number 6 designates the position of the pipes welded.